Non-bottleneck resource:

An Hour Saved at a Non-bottleneck is Just a Mirage

For a non-bottleneck resource, there is some idle time, throughout which either this resource is unutilized or generating inventory pile-up. Even in case of the functioning or processing time of this resource is crashed; the total impact on the system shall be zero so far as throughput is concerned. It is because throughput is dictated by the bottleneck resource. Thus, TOC advocates attack on bottleneck for enhancing its efficiency.

Let us look at the set-up time, which is required for setting the tool/machines, etc. for each of the batch of part-processing. Traditional system treats set-up time equally for bottleneck and non-bottleneck resource. TOC advocates different approaches.

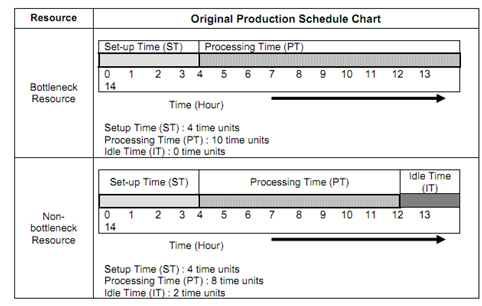

In Figure (a), an instance is presented. In this, the bottleneck resource procedure one batch of part in 14 time units (hour), whereas non-bottleneck does it in 12 time units (therefore, has 2 units of idle time per batch). The processing of batch of this part first goes to bottleneck, followed by the non-bottleneck. Originally, because of lesser processing time (PT) on the non-bottleneck, on non-bottleneck there is an idle time (IT) of 2 hours. while, the set-up of bottleneck is squeezed by one hour, the idle time of non-bottleneck decreased by one hour and the system throughput increases because of faster disposal : at bottleneck. Thus, when the set-up of non-bottleneck is squeezed by one hour, its idle time enhanced by one hour due to no change at bottleneck resource. Throughput remains similar.

Figure (a): Original Production Schedule Chart