Design Procedure:

The subsequent steps are adopted for mix design:

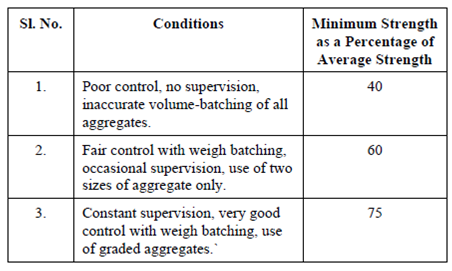

(a) The average compressive strength of the mix to be designed is obtained by applying the control factors to the minimum compressive strength. Table 6 shows the relation between compressive strength and water-cement ratio and it depends upon the degree of quality control.

Table: Relation between Minimum and Mean Compressive Strengths

(b) The water-cement ratio needs to give the desired necessary average compressive strength can be obtained directly from the curve of Figure.

(c) The proportion of merged aggregate to cement is determined for aggregates of max Size 40 mm and 20 mm, correspondingly.

(d) The excellent aggregates and coarse aggregates must be combined so as to produce one of the standard grading if the aggregates available at the works site differ from the standard grading.

(e) The proportion of cement, excellent aggregate, coarse aggregate and water is determined by using knowledge of aggregate-cement ratio and water-cement ratio of the mix.

(f) To generates 1 m3 of concrete the quantities of ingredients required is calculated with the absolute volume method by using the specific quantities of cement and aggregate.