Fillet Welds:

Geometrical Properties

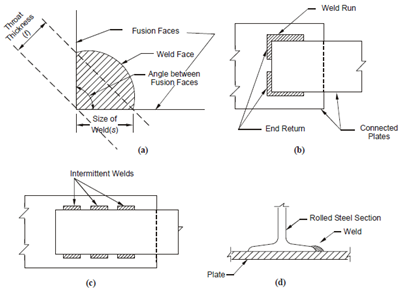

The geometrical properties and definitions used in case of fillet welds are shown in Figure.

Figure

(a) Size of the fillet weld shall be took as, either

(i) The minimum leg length of a convex (or flat) fillet weld;

Or (ii) 1.41 times the effective throat thickness of a concave fillet weld.

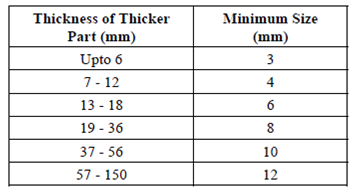

(b) A minimum size of the fillet weld shall be related to the thickness of the connected plates as in Table.

(c) A maximum size of the fillet weld should be the thickness of the connected part minus 1.5 mm.

Table: Minimum Size of Fillet Weld (As per IS 9595: 1980)

* For the greater than 150 mm thick plates, special precautions (like pre-heating) should be taken.

** To rolled steel sections, the size of fillet weld shall be 75% of the thickness of the toe section as shown in Figure (d).

(d) Angles among the fusion faces shall be between 60o to 120o for effective transmission of load.

(e) The throat thicknesses for several angles are given in Table.