Standard Reverberatory:

Usually these are of a rectangular or square shape and might be either tilting or static. Normally Scrap is charged in through the chief furnace door in either lose or baled format. Dross shall float to the surface and, unless eliminated, might hinder heat transfer to the molten metal. The major furnace door need to be opened to charge material or to dross off, giving increase to a substantial heat loss through the furnace. If decoated material is to be fed into these kinds of furnaces the usually material is permitted to cool and then is baled prior to charging. It means that the heat energy had in the scrap throughout decoating is lost. Characteristics of this kind of furnace include following:

- Batch type operation

- Low capital cost

- Low recoveries

- Exhaust gases may require treatment

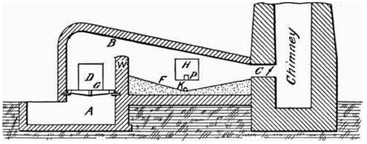

Figure: Reverberatory Furnace