Reinforced Earth Walls

The use of reinforcement to strengthen the soil has been called for centuries. Straw has been used to strengthen unburnt bricks and fascine mattresses have been used to strengthen soft soil deposits prior to road construction. The principle of reinforced earth is in which a mass of soil could be given tensile strength in an exact direction if lengths of a material capable of carrying tension are embedded inside it in the needed direction. A rational approach to the design of reinforced earth was presented through Vidal in 1966. Reinforced earth has been used in several geotechnical applications. Here, we are only concerned along with retaining structures.

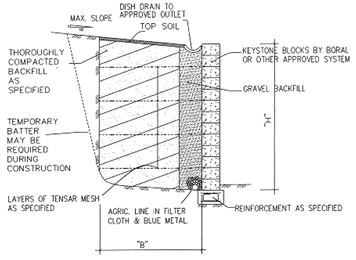

A reinforced earth wall is a gravity structure. A simple form of such a wall is illustrated in Figure 8. The components listed are described below:

Figure : Reinforced Earth Walls

The soil fill should be granular and free draining. The reinforcing elements could be either geosynthetics or metal strips. This metallic strips, 50-100 mm wide and 3 to 5 mm thick, are commonly used. Metal grids have also been employed within some cases. Galvanised steel strips are the most general reinforcement. Aluminium alloy, copper and stainless steel are another metals used. All these materials have a high modulus of elasticity and negligible strains are created inside the soil mass.

There has been rising use of geosynthetics as reinforcement within reinforced earth from the year 1975. Woven geotextiles and geogrids have the benefits of greater durability than metals within corrosive soil. Their tensile strength could approach which of steel. Geogrids could achieve high frictional properties among itself and the surrounding soil. Thus, all the geosynthetics undergo creep deformation under sustained loading that could lead to large strains inside the soil mass.

At the boundary of reinforced earth structure it is essential to give a facing so in which fill is contained. The facing does not contribute to the structural strength of the wall. The facing is commonly built up from prefabricated units small and light enough to be handled through manual labour. The most common facing material is precast concrete by steel; aluminium and plastic units have been used. A concrete foundation is needed to form a platform from that facing units could be built up.

Reinforced earth could give a satisfactory method for retaining soil while existing conditions do not permit construction through conventional methods. A compressible soil might be capable of supporting a reinforced earth structure although pile foundation might be needed in the case of cantilever or gravity walls. The technique could also be used while there is insufficient and space to construct the sloping side of an earthen embankment.

Please remember that in developed countries reinforced earth is frequent the first selected for design engineers while considering an earth retaining structure.