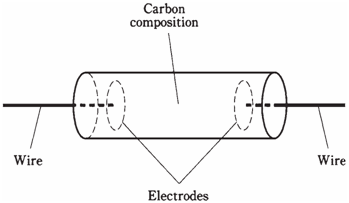

Carbon-composition resistor

The cheapest method of making a resistor is to mix up finely powdered carbon (which is a fair electrical conductor) with some nonconductive substance, press the resulting clay-like stuff into a cylindrical shape, and insert wire leads in the ends. The resistance of final product will depend on the ratio of carbon to nonconducting material, and on physical distance between the wire leads. The nonconductive material is phenolic and is similar to plastic. This results in carbon-composition resistor.

Carbon-composition resistors can be made to posses quite low resistances, all the way up to very high resistances. This kind of resistor has the advantage of being nonreactive. That means that it introduces almost pure resistance in the circuit, and not much inductance or capacitance. This makes the carbon-composition resistor useful in the radio transmitters and receivers.

Figure-- Construction of the carbon-composition resistor.

Carbon composition resistors dissipate power according to physically, there size. Most of the carbon composition resistors which you see in the electronics stores can handle 1⁄4 W or 1/2 W. There are 1/8-W units for the miniaturized, low power circuitry, and 1-W or 2-W components for circuits where some electrical ruggedness is required. Occasionally you will see a much larger unit, but these are quite rare.