Vapour Compression Systems:

The challenge in refrigeration & air conditioning is to eliminate heat through a low temperature source & dump it at a high temperature sink. Compression refrigeration cycles generally take advantage of the idea that extremely compressed fluids at one temperature shall tend to get colder while they are permitted to expand. If the pressure modify is high sufficient, then the compressed gas shall be hotter than our source of cooling (outside air, for example) and the expanded gas shall be cooler than our desired cold temperature. In this particular case, we may use it to cool at a low temperature and discard the heat to a high temperature.

Vapour-compression refrigeration cycles particularly have two added advantages. Primary, they exploit the large thermal energy needed to change a liquid to a vapour so we can eliminate lots of heat out of our air-conditioned space. Secondly, the isothermal nature of the vaporization permits extraction of heat without enhancing the temperature of the working fluid to the temperature of whatever is being cooled up. It is advantage because the closer the functioning fluid temperature approaches that of the surroundings, the lower the rate of heat transfer. The isothermal procedure permits the fastest rate of heat transfer

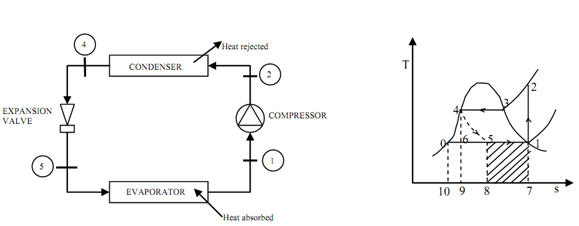

Vapour compression refrigeration is the prime method to offer mechanical cooling. All vapour compression systems contain following four basic components along with the interconnecting piping. These are the compressor, evaporator, condenser & the expansion valve. Typical vapour compression systems may be represented as shown in figure

(a)Schematic Representation of a Vapour figure (b) T-S Diagram