Vapour Absorption System:

The vapour absorption refrigeration is a heat operated system. This is quite similar to the vapour compression system. In both of the systems, there are evaporator & condenser. The procedure of evaporation & condensation of the refrigerant occurs at two distinct pressure levels to attain refrigeration in both of the cases. The technique employed to make the two pressure levels in the system for evaporation & condensation of the refrigeration makes the two procedures different. Circulation of refrigerant in both of the cases is also different.

In the absorption scheme the compressor of the vapour compression scheme is replaced by the combination of "absorber" & "generator". A solution called as the absorbent, that has an affinity for the refrigerant utilized, is circulated among the absorber & the generator through a pump (solution pump). In the absorber, absorbent sucks (or draw) the refrigerant vapour built in the evaporator therefore maintaining a low pressure in the evaporator to make able the refrigerant to evaporate at low temperature. In the generator the absorbent is heated up. There by releasing the refrigerant vapour (absorbed in the absorber) like high pressure vapour, to be condensed in the condenser. Therefore the suction function is carry out by absorbent in the absorber & the generator carry out the function of the compression & discharge. The absorbent solution carries the refrigerant vapour through the low side (evaporator-absorber) to the high side (generator-condenser). The liquefied refrigerant pass from the condenser to the evaporator because of the pressure difference among the two vessels; therefore establishing circulation of the refrigerant via the system.

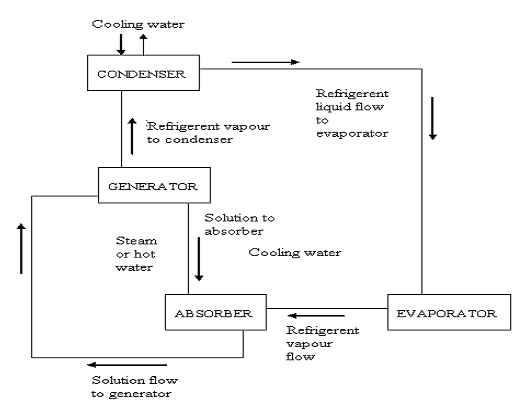

Given fig is a schematic diagram of the absorption cycle. Since it can be seen from the diagram, the refrigerant & absorbent have separate flowing paths. The refrigerant path is:

Evaporator →Absorber →Generator → Condenser →Evaporator & for the absorbent this is,

Absorber → Generator → Absorber

The absorbent solution flowing from the generator to the absorber is hot & ha to be cooled. Conversely the absorbent solution sent to the generator is cooled & ought to be heated for the regeneration of the refrigerant in the generator. A shell & tube heat exchanger is introduced among the generator & the absorber.

Diagram of Absorption System of Refrigeration

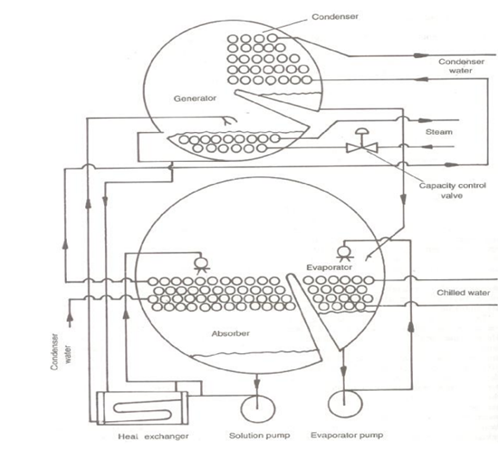

Sketch of a Lithium-Bromide Absorption Machine - Single Stage

There is several vapour absorption system based on the absorbent for example lithium bromide absorption system, ammonia absorbent system, etc. Ammonia absorbent systems were utilized in the early stages of refrigeration. This system utilizes ammonia like the refrigerant & water as absorbent. In lithium bromide absorption system lithium bromide salt solution is utilized as the absorbent & water like the refrigerant. A concentrated solution of lithium bromide contains a high affinity for water. As water is the refrigerant, the refrigerant functioning temperature in the evaporator ought to be above the freezing point of water (0oC) of water.