Tungsten and its Alloys

Tungsten has highest melting point temperature at 3410oC and the highest density .Its modulus of elasticity is also highest. With oxidation coating W might be utilized as a structural material up to 2480oC. It has good dimensional stability at elevated temperature because of low coefficient of thermal expansion, good thermal conductivity and low vapour pressure.

Due to high density and melting point W forms alloys with only a few elements Rhenium dissolves in tungsten up to 26%. Upto 5% Re in tungsten helps enhance recrystallization temperature, hot strength, and electrical resistivity. Re-addition also enhances low temperature ductility. W-1.5% Re & W-3% Re alloys are utilized for lamp filaments and thermocouples. A ternary alloy W-3.6% Re-0.15% Hf has exceptionally high strength at elevated temperatures because of dispersion of carbide of Hf. Thermionic electron emission of W enhance by addition of 1-2% thoria. This alloy also has enhanced strength at high temperature.

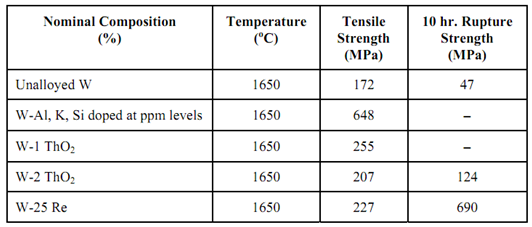

AKS alloys of W are basically W-1% ThO2 alloy doped with small amounts of aluminium, potassium & silicon. These alloys might be treated to attain recrystallization temperature greater than 1800oC. These alloys have long grains that tend to interlock. Long use at elevated temperature might not result in permanent deformation as is needed in electric bulbs or lamps. Some alloys of W are explained in Table .

Table: Composition and Strength of Some Tungsten Alloys