Molybdenum and its Alloys

Mo is most commonly available & least expensive element of the refractory metals described here. The complexity with Mo is its brittleness at room temperature which has greatly decreased its possibility of widespread application. Though, there exist areas of applications where still high temperature strength, good corrosion resistance and relatively high electrical and thermal conductivity might be used.

Mo is added to low alloy steel, cast irons, tool steels, stainless steel and super alloys as alloying element. Mo generates following effects in above materials.

1. Enhance toughness and hardenability of low alloy steels.

2. Enhance corrosion resistance of stainless steel.

3. Enhance high temperature strength and corrosion resistance of super alloys.

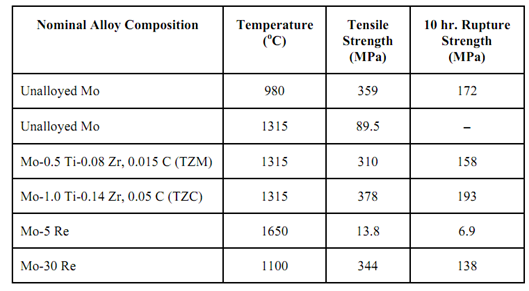

Four Mo alloys are commonly utilized. Table explained their composition, high temperature tensile strength & 10 hr. creep rupture strength.

Table: Properties of Mo and its Alloys

The TZM alloy offers better behaviour at elevated temperature than unalloyed Mo which loses strength because of softening & recrystallization. Its creep resistance is also higher above 1000oC. In TZM alloy strengthening takes place because of precipitation of complex Mo-Ti-Zr carbides. It has been discovered that high temperature behaviour of TZM may be further enhanced by nitriding.