Random Search Optimization Techniques Or Rsopt To Resolve Operation And Scheduling Problems

Characteristics of Operation and Scheduling Problems

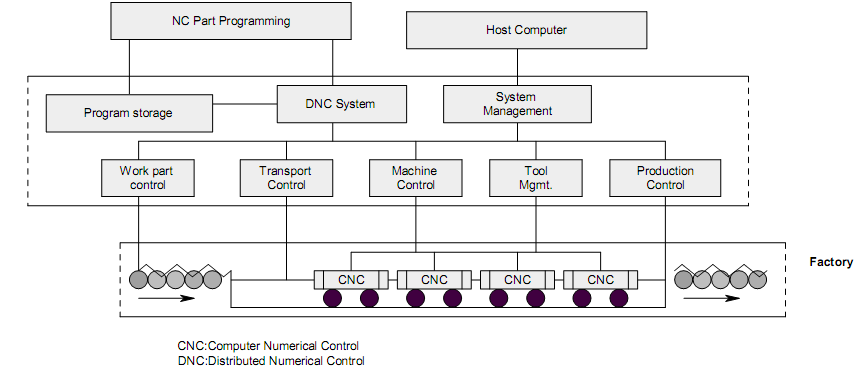

Scheduling is taken to be one of the critical parts of any type of manufacturing system such has a direct influence upon the system productivity. Mostly Scheduling deal along with the allocations of different resources to the activities into order to meets the inputs require in a cost and time effective manner. Whilst performing scheduling, the information concerned to start time and end time of the activity are termed in advance. Generally, there are different types of constraints associated along with scheduling that should be satisfied to be considered any type of schedule like a feasible schedule. A figure such describing the basic workflow of planning and operation in flexible manufacturing system is described in figure.

CNC: is Computer Numerical Control

DNC: is Distributed Numerical Control

Figure: An Overall Workflow in a Manufacturing System

The general objective related with the scheduling is the minimization of make span that is nothing however, the completion time of last operation in a sequence. Conversely, several other objectives are optimized also beneath scheduling aspect, as:

(a) Maximization of utilization of resources

(b) Minimization of Work in Process or WIP inventory

(c) Minimization of customer waiting time

(d) Maximization of total profit.