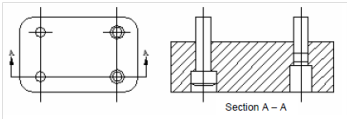

Plain Punch

This category of punch is economical and simple to operate. It is an easy block of hardened tool steel. The shape of punch depends upon the needed profile. Plain punch is directly mounted onto the punch holder of die set. A plain punch is display in Figure. While extra length is required, plain punch is mounted on to the flat punch plate. Screws and dowels hold plain punch in the similar way as they hold solid die blocks. The length and width of plain punch should at least be equal to the punch height for the stability. While high and unbalanced blanking and piercing pressures are required, it is essential to use heights greater than either punch length or width. In such conditions, some other type of punch should be considered.

Figure: Plain Punch

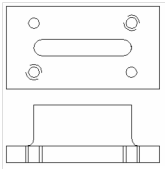

These are constructed through machining in a way which leaves a flange around the base of the punch. The pedestal punch is display in Figure. Its base area is larger than its cutting face area. Pedestal punches are advantageous since of large base and solid construction, thus, are stable. As cutting force distributed uniformly over large base, pedestal punches are capable of withstanding heavy cutting force. The flange of pedestal punch should be huge and thick sufficient to gives space for holes. These holes are used for mounting.

Figure: Pedestal Punch