MAP and TOP

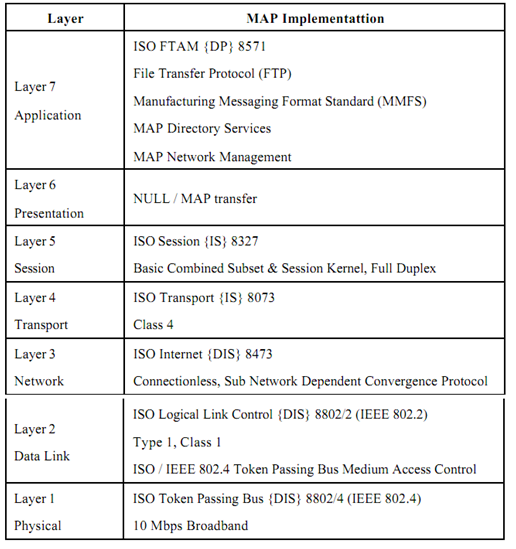

The manufacturing automation protocol (MAP) was built up by General Motors to meet its manufacturing integration requirements. Sometimes the networks for different products of the similar vendors are not always compatible. To link these products directly in a communication network becomes a seemingly impossible task. Alternatively, to implement a computer-integrated system, it is needed to have communication among different factory devices such as robots, cell controllers, NC machines, and area controllers. MAP supports application-layer protocols such like manufacturing messaging specifications (MMS), intended for real time communication among such devices. The different layered approach of MAP, as illustrated in the Table, permits new technology to be incorporated while it becomes available. It utilizes the ISO reference model & coordinates with the Technical & Office Protocol (TOP) developed by Boeing Company for office communications, and other standards. MAP and TOP share the standards on many layers. The difference is on the physical layer, where TOP is depends on the CSMA/CD bus of Ethernet. A gateway might easily be built to bridge the two networks. With TOP and MAP, not only communication within a manufacturing shop might be ensured, but also a link to the corporation office might be established.

Given table describes the TOP and MAP specifications as given by IEEE.

Table: MAP 2.1 Standard