Example of Proportional Plus Reset Control:

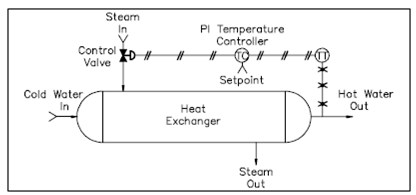

Let's once more refer to our heat exchanger example display in the below figure. This time we will apply a proportional plus reset controller to the procedure system.

Figure: Heat Exchanger Process System

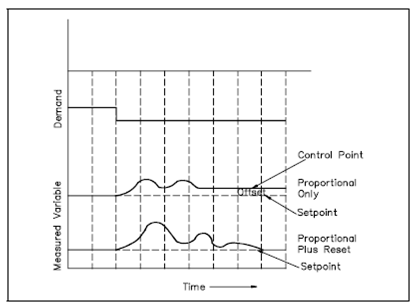

The response curves displays in Figure describe only the demand and the measured variable that represents the hot water outlet temperature.

Suppose the process undergoes a demand disturbance that decreases the flow of the hot water out of the heat exchanger. The temperature and flow rate of the steam into the heat exchanger remain the same. Conclusion, the temperature of the hot water out will start to increase.

A proportional action of the proportional plus reset controller, if acting alone that would respond to the disturbance and reposition the control valve to a position which would return the hot water out to a new control point, as described through the response curves. You'll note in which a residual error would still exist.

Figure: Effects of Disturbance on Reverse Acting Controller

Through adding the reset action to the proportional action the controller generates a larger outcome for the given error signal and causes a greater adjustment of the control valve. This causes the procedure to come back to the setpoint more fastly. Further, the reset action acts to eliminate the offset error after a period of time.