Material Requirement Planning:

Globalization has left several service-oriented companies and manufacturing industries with the alternative of pursuing world's best practices. Now many companies comprehend the need for the development of methodologies, as well as acquiring the new productivity tool such as MRP (Material Requirement Planning), BOM (Bill of Material), Master Production Schedule (MPS), MRP II etc., that shall let them be in a commercial position to offer competitive Manufacturing Resource Planning. It assure customers about quality goods and services, and compliance them with international quality requirements on different industry fields.

Material Requirement Planning (MRP) initiates with the principle that several materials held in inventory are generally dependent on demands. Materials are of two types: raw material kept in inventory and partially complete products held in process inventory. The raw material quantity of a particular material with dependent demand that is required in any week, depend on the number of products to be produced that needs the material. The demand for raw materials and partially completed products does not have to be forecasted, because if it is known what finished products must be produced in a week, the amount of each of material needed to produce these finished products can be calculated.

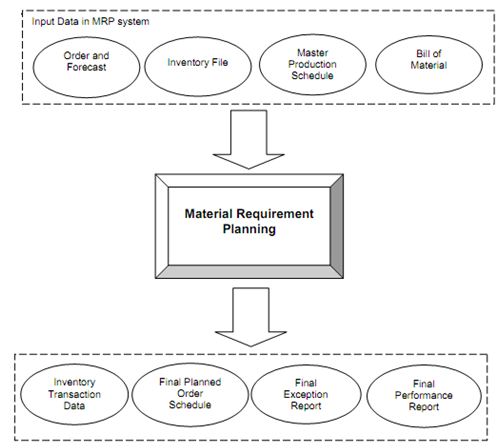

The basic structure of MRP system is shown in Figure. Normally it is a computer-based system that takes the Master Production Schedule (MPS) as given, explodes the MPS into the needed amount of raw materials, subassemblies, parts, and assemblies needed in each week of the planning horizon; reduces these material requirements to account for materials that are in inventory or on order; and develops a schedule of orders for purchased materials and produced parts over the planning horizon.

Figure: Basic Structure of MRP System

Objectives

After learning this unit, you should be able to

- understand material requirement planning,

- learn the principle of MRP,

- know the significant factors affecting MRP,

- explain bill of material and master production schedule, and

- Understand manufacturing resource planning.