Shape Complexity

Shape is a necessary feature of all manufactured parts; complexity of the part shape often determines what process may be considered for making it. In the most general sense, rising complexity narrows the range of processes that may be used and increases cost. A cardinal rule of design is, thus to keep the shape as simple as possible. The rule might however be broken if a more complex shape allows consolidation of many parts and/or removal of one or more manufacturing steps.

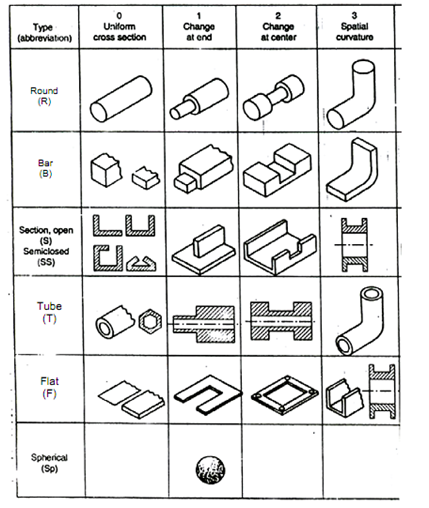

There is no universally accepted shape classification system. Products of uniform cross section (spatial complexity = 0) are two-dimensional, all others are three-dimensional. With increasing spatial complexity, definition of the shape requires additional geometric parameters. A small increment in information content can, however, have significant manufacturing consequences. For example, in Figure 1 moving from solid shape R1 to the hollow shape T1 adds only one dimension (the diameter of the hole, with appropriate tolerances and specifications for concentricity), yet it immediately excludes some processes or necessitates extra operations in others. Adding a third diameter to the round product R1 would result in the same increase in information content yet does not impose limitations of process choice.

Figure 1 : The Choice of Possible Manufacturing Methods is Aided by Classifying Shapes According to Their Geometric Features