Concepts of Capability Studies

Process capability is a measurement with respect to the inherent precision of a manufacturing process. As a definition:

Process capability is quality-performance capability of the process with given factors and under normal, in-control conditions.

Two important elements in this concept of process capability are :

- Process factors

- Process conditions

The first consideration necessary to the concept of process capability is that a process is made up of a number of different factors. These factors involve raw material, machine or equipment, the skill of operator, measuring devices, and the measurer's skill. A change in one or more of these factors may change the process capability. Hence, to be meaningful, a process capability must be stated with respect to a given set of specifically listed process factors.

The second element contained in the definition is that involving process conditions. For a process-capability study to be meaningful, the process being analyzed should be one that has measurements normally distributed and in a state of statistical control.

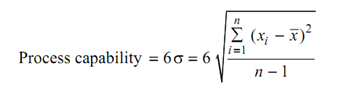

Mathematically, the process capability is defined as six standard deviation units (6 σ).

99.73 percent of all the readings for a normal distribution fall within the area bounded by

+ 3 standard deviation units from the mean. So, a process capability study, mathematically, is merely a well-organized, carefully disciplined frequency distribution analysis of the appropriate process data. The formula for the process capability is, therefore, shown as :

where σ = Standard deviation of sample population,

xi (where i = 1 to n) = Individual measurements,

x = Average of individual measurements, and

n = Number of individual measurements (total nos. of measurements).