Punch Support

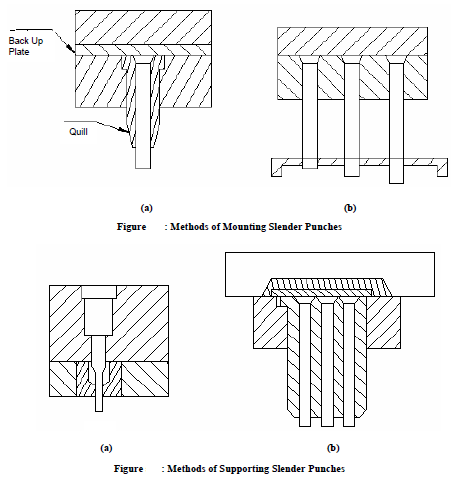

Diameter of piercing punches should not be smaller than thickness of the strip that is to be pierced. If diameter of piercing punch is smaller than thickness of the strip, diameter of punch shank should be at least double the whole size and cutting face should be ground to the whole size for a distance about double the stock thickness. The punches having more than 4 inch unguided length are avoided. If the length of the punch is more than 4 inch, a spacer block should be used in among punch and punch plate. Several techniques of supporting slender punches are display in Figures. A quill which is used to increase the strength of slender punch is display in Figure (a). The punch is made up of tool steel and could be simply replaceable if it fails. The punch is assembled in a quill with tight press fit. The quill is made up by the mild steel.

Slender punches in stripper plate are supported and guided through sliding fit is shown in Figures (b) and (a). The use of more than one perforator in a one quill is display in Figure (b). This allows piercing little holes near to every other.