Punch Shedders

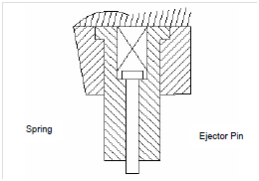

The slug and blank sticks to the punch face and comes out with punch during blanking & piercing operation. The slug sticks to the die wall because of spring back in the blank and slug during normal operation. While the amount of spring back is proportionate to the stock thickness and area of slug, small holes within thin material show very little spring back and doesn't stick to the die wall. Therefore slug may adhere to the punch face. Slug may also stick to the punch face because of heavy lubrication. Sticking of slug can be decreased through using low viscosity lubricants. The sticking of slug can also be decreased by using shedder pins. Shedder pins break the oil bond among punch face and slug. Shedder pins break the bond among punch face and slug. The spring operation of shedder pin is display in Figure. The shedder pin is situated in the centre of the punch. The use of shedder pin is limited only for punches of diameter greater than 3/32 inch. For diameter below 3/32 inch, concave shear may be given on the face of the punch. This helps to prevent it from sticking to the punch face.

Figure: Spring Actuated Shedder Pins