Construction:

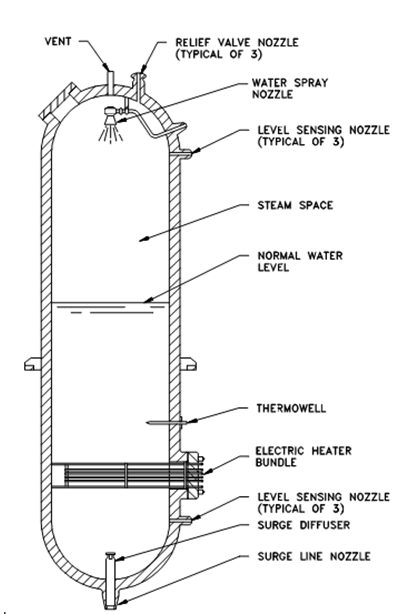

A dynamic pressurizer is constructed from a tank equipped along with a heat source like as electric heaters at its base, a source of cool water, and a spray nozzle. A spray nozzle is a device situated within the top of the pressurizer which is used to atomize the incoming water.

A dynamic pressurizer must be linked in the system to permit a differential pressure to exist across it. A bottom connection, also known as the surge line, is the lower of the two pressure lines. The top connection, referred to as the spray line, is the higher pressure line. Differential pressure is acquired through connecting the pressurizer to the suction and discharge sides of the pump servicing the particular system. Exclusively, the surge (bottom connection) is linked to the pump's suction side; the spray line (top connection) is linked to the pump's discharge side. A general pressurizer is described in Figure.

The hemispherical top and bottom heads are commonly constructed of carbon steel, along with austenitic stainless steel cladding on all surfaces exposed to the reactor system water. A pressurizer could be activated in two ways. Partially filling the pressurizer along with system water is the first. After the water reaches a predetermined level, the heaters are engaged to rise water temperature. While the water reaches saturation temperature, it starts to boil. Boiling water fills the void above the water level, making a saturated environment of water and steam. The other techniques includes filling the pressurizer completely, heating the water to the desired temperature, after that partially draining the water and steam combination to make a steam void at the top of the vessel.

Figure: Basic Pressurizer

Water temperature denotes the amount of pressure established within the steam space and the greater the amount of time the heaters are engaged, a hotter the environment becomes. As the hotter the environment as the greater the amount of pressure.

Installing a control valve within the spray line makes it probable to admit cooler water from the top of the pressurizer by the spray nozzle. Lowers the existing water temperature, adding cooler water condenses the steam bubble, and decrease the amount of system pressure.