Bellows-Type Detectors:

The requirement for a pressure sensing element which was extremely sensitive to low pressures and given power for activating recording and denoting mechanisms resulted in the development of the metallic bellows pressure sensing element. A metallic bellows is extremely accurate while measuring pressures from 0.5 to 75 psig. Therefore, while used in conjunction along with a heavy range spring, a few bellows could be used to measure pressures of over 1000 psig. Figure display a basic metallic bellows pressure sensing element.

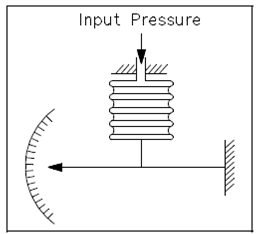

Figure: Basic Metallic Bellows

The bellows is a one-piece, collapsible, seamless metallic unit which has deep folds formed from extremely thin-walled tubing. A diameter of the bellows ranges from 0.5 to 12 in. and might have as several as 24 folds. A System pressure is applied to the internal volume of the bellows. Since the inlet pressure to the instrument varies, the bellows will expand or contract. The moving end of the bellows is linked to a mechanical linkage assembly. As the bellows and linkage assembly moves, either an electrical signal is provided or a direct pressure indication is given. The flexibility of a metallic bellows is same in character to which of a helical, coiled compression spring. Up to the elastic limit of the bellows, the relation among increments of load and deflection is linear. Therefore, this relationship exists only while the bellows is under compression. It is must to construct the bellows such in which all of the travel occurs on the compression side of the point of equilibrium. Thus, in practice, the bellows must always be opposed through a spring, and the deflection features will be the resulting force of the spring and bellows.