Press Working Terminology

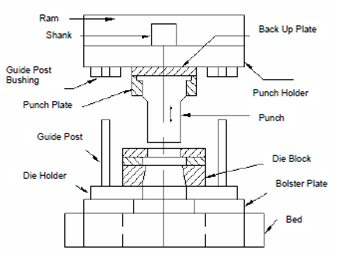

An easy cutting die is shown in Figure.

Figure: Simple Cutting Die

Bed

The bed is lower part of press frame which serves as a table on that a bolster plate is mounted.

Bolster Plate

Bolster plate is a thick plate secured to the press bed that is used for locating and supporting the die assembly. Its thickness is commonly 5 to 12.5 cm.

Die Set

Die set is unit assembly that incorporates a lower and upper shoe, two or more guide posts & guide post bushings.

Die

Die is the female part of a complete tool for producing work in a press. It is also referred to a finished tool consisting of pair of mating members for producing work in press.

Die Block

It is the block or a plate that contains the die cavity.

Lower Shoe

The lower shoe of a die set is commonly mounted on the upper plate of a press. A die block is mounted on the lower shoe. A guide posts are also mounted in it.

Punch

Punch is the male elements of the die assembly that is directly or indirectly moved by or fastened to the press ram or slide.

Upper Shoe

It is the upper element of the die set that contains die post bushings.

Punch Plate

The punch plate/punch retainer fits closely over the body of the punch & holds it in proper relative position.

Back Up Plate

It is also known as pressure plate. It is placed so in which the intensity of pressure does not become excessive on punch holder. The plate distributes a pressure over a huge area and intensity of pressure on the punch holder is reduced to prevent crushing.

Stripper

Stripper is a plate that is used to strip the metal strip from a cutting or non-cutting punch or die. It mighit also guide the strip.

Knock Out

Knock out mechanism is used to erase the workpiece from a die. It is connected to and operated through the press ram.

Pitman

Pitman is a connecting rod that is used to transmit the motion from the major drive shaft to the press slide.