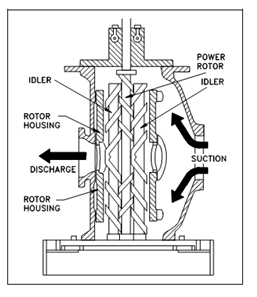

Three-Screw, High-Pitch, Screw Pump:

Figure: Three-Screw, High-Pitch, Screw Pump

The three-screw, screw pump, high-pitch, displays in Figure, has several of the similar components as the two-screw, screw pump, low-pitch, and their operations are same. Three screws, oppositely threaded on each end, are employed. They rotate within a triple cylinder, a two outer bores of that overlap the center bore. A pitch of the screws is much higher than in the low pitch screw pump; thus, the center screw, or power rotor that is used to drive the two outer idler rotors straightly without external timing gears. Pedestal bearings at the base support the weight of the rotors and manage their axial position. A liquid being pumped enters the suction opening, flows by passages around the rotor housing, and by the screws from each end, in opposed streams, toward the center discharge. This eliminates unbalanced hydraulic thrust. A screw pump is used for pumping viscous fluids, commonly lubricating, hydraulic, or fuel oil.