Power Pumps:

Power pumps convert rotary motion to low speed reciprocating motion through reduction gearing, connecting rods, a crankshaft and crossheads. Plungers or pistons are driven through the crosshead drives. Piston and Rod construction, same to duplex double-acting steam pumps, is used through the liquid ends of the low pressure, higher capacity units. A higher pressure unit is generally single-acting plungers, and common employs three (triplex) plungers. Three or more plungers substantially decrease flow pulsations associative to simplex and even duplex pumps.

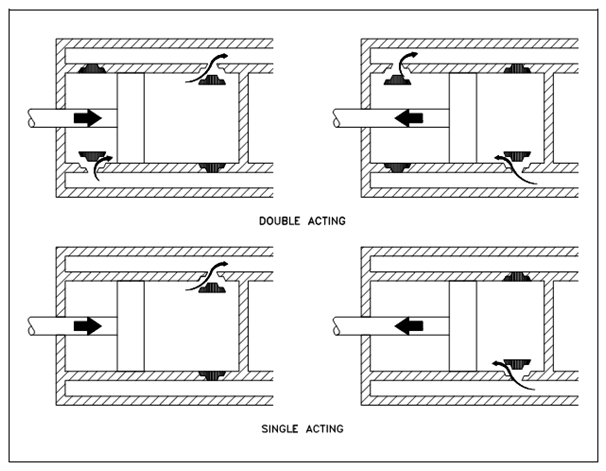

Figure: Single-Acting and Double-Acting Pumps

Power pumps classically have high effectiveness and are capable of developing extremely high pressures. They could be driven through either electric motors or turbines. They are associatively expensive pumps and could rarely be justified on the basis of efficiency over centrifugal pumps. Therefore, they are often justified over steam reciprocating pumps where continuous duty service is required because of the high steam requirements of direct-acting steam pumps.

In common, the effective flow rate of reciprocating pumps decreases as the viscosity of the fluid being pumped increases since the speed of the pump must be decrease. In compare to centrifugal pumps, the differential pressure provided through reciprocating pumps is independent of fluid density. It is dependent whole on the amount of force exerted on the piston. For more data on density, viscosity, and positive displacement pump theory, refers to the handbook on Heat Transfer, Thermodynamics and Fluid Flow.