Reducing Valves:

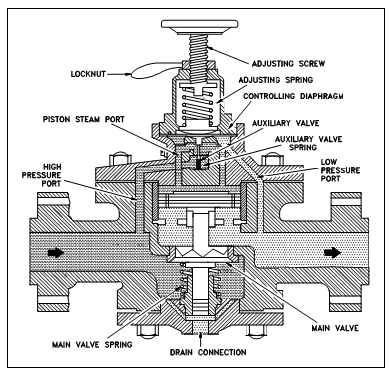

Reducing valves automatically decrease supply pressure to a preselected pressure as long as the supply pressure is at least as high as the selected pressure. As described in Figure, the principal categories of the reducing valve are the main valve; an upward-seating valve which has a piston on top of its valve stem, an upward-seating auxiliary (or controlling) valve, a controlling diaphragm, and an adjusting spring and screw.

Figure: Variable Reducing Valve

Reducing valve operation is controlled through high pressure at the valve inlet and the adjusting screw on top of the valve assembly. A pressure entering the major valve assists the main valve spring in keeping the reducing valve closed through pushing upward on the major valve disk.

Therefore, a few of the high pressure is bled to an auxiliary valve on top of the main valve. An auxiliary valve controls the admission of high pressure to the piston on top of the main valve.

The piston has larger surface fields than the major valve disk, resulting in a net downward force to open the main valve. An auxiliary valve is controlled through a controlling diaphragm situated directly over the auxiliary valve.