Diaphragm Valves:

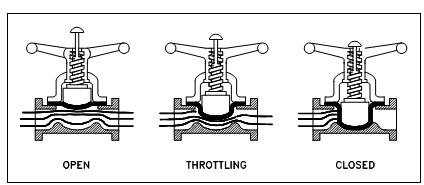

A diaphragm valve is a linear motion valve which is used to start, regulate, and stop fluid flow. A name is derived from its flexible disk that mates along with a seat situated in the open area at the top of the valve body to form a seal. A diaphragm valve is described in Figure.

Figure: Straight through Diaphragm Valve

Diaphragm valves are simple, in effect, "pinch clamp" valves. A resilient, flexible diaphragm is linked to a compressor through a stud molded within the diaphragm. A compressor is moved up and down through the valve stem. Therefore, the diaphragm lifts while the compressor is raised. Since the compressor is lowered then the diaphragm is pressed against the contoured bottom in the straight by valve described in Figure or the body weir within the weir-type valve described in Figure.

Diaphragm valves could also be used for throttling service. A weir-type is the better throttling valve but has a limited range. Its throttling features are necessary those of a quick opening valve since of the huge shutoff area along the seat.

A weir-type diaphragm valve is available to control small flows. It uses two-piece compressor elements. Alternatively of the entire diaphragm lifting off the weir while the valve is opened, a first increment of stem travel raises an inner compressor component which causes just the middle part of the diaphragm to lift. This makes an associatively small opening through the middle of the valve. After the inner compressor is fully open, the outer compressor elements is raised along with the inner compressor and the remainder of the throttling is same to the throttling that takes place within a conventional valve.

It valves are particularly suited for the handling of corrosive fluids, radioactive fluids, fibrous slurries, or other fluids which must remain free from contamination.