Diaphragm Construction:

The operating mechanism of a diaphragm valve is not exposed to the media within the pipeline. Viscous or Sticky fluids cannot get within the bonnet to interfere along with the operating mechanism. Several fluids which would clog corrode, or gum up the working elements of most other categories of valves will pass by a diaphragm valve without causing problems. On the other hand, lubricants used for the operating mechanism cannot be permitted to contaminate the fluid being handled. There are no packing glands to manage and no possibility of stem leakage. There is a huge choice of available diaphragm materials. Diaphragm life depends upon the nature of the material handled, pressure, temperature, and frequency of operation.

A few elastomeric diaphragm materials might be unique in their excellent resistance to certain chemicals at high temperatures. Therefore, the mechanical properties of any elastomeric material will be lowered at the higher temperature along with probable destruction of the diaphragm at high pressure. On the other hand, the manufacturer should be consulted while they are used in elevated temperature applications.

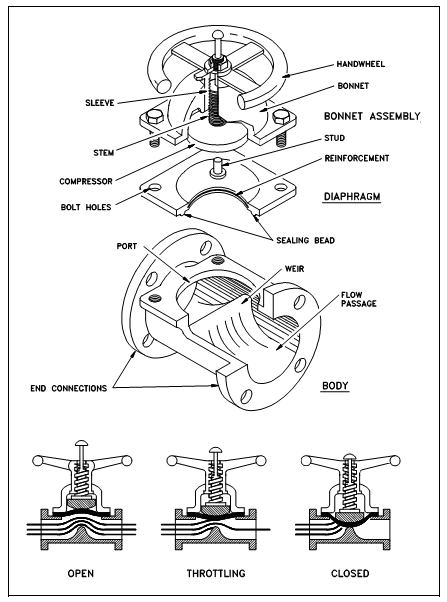

Figure: Weir Diaphragm Valve

All elastomeric materials operate best below 150°F. A few will function at higher temperatures. Viton, for instance, is noted for its excellent chemical resistance and stability at high temperatures. Therefore, while fabricated within a diaphragm, Viton is subject to lowered tensile strength only as any other elastomeric material would be at elevated temperatures. Fabric bonding strength is also lowered at elevated temperatures, and in the case of Viton, temperatures might be reached whereas the bond strength could become critical.

Fluid concentrations are also a consideration for diaphragm selection. Several of the diaphragm materials exhibit satisfactory corrosion resistance to definite corrodents up to an exact concentration and/or temperature. The elastomer might also have a maximum temperature limitation based on mechanical properties that could be in excess of the permitted operating temperature depending upon its corrosion resistance. That should be checked from a corrosion table.