Rubber

It is a plastic which is largely derived from natural sources and utilized in a modified form. Rubber is well called as material for automobile tyres. It belongs to a broad class which is known as elastomer and has a property of large extension. An elastomer might extend 100 to 1000% under applied force.

Natural rubber, known as polyisoprene, is attained from trees like a colloidal dispersion in the milky liquid, called as rubber latex. This material is extremely soft in its semisolid state and is converted into sheets by coagulation with acids & passing among the rolls. This rubber sheet called as crop rubber or smoked sheet does not have much strength unless vulcanised at a high temperature for making cross links among molecular chains. The hardness of rubber based upon degree of cross linking –harder the rubber, higher the cross linking. Highly vulcanised natural rubber, called as ebonite, is very hard. Natural rubber is chlorinated by passing HCl through the benzene solution of natural rubber. The product so attained is converted into thin adhesive tapes. Hot melt coating for paper is generated from isomerised rubber dissolved in aromatic or aliphatic compounds. Isomerisation is a procedure in which rubber molecules are rearranged in cyclic form.

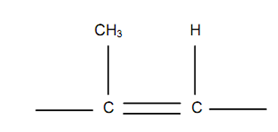

The natural rubber monomer is isoprene that is represented as

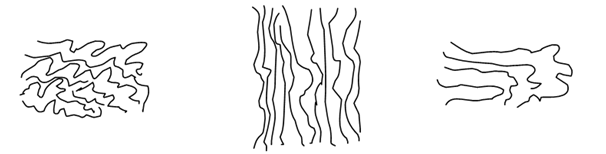

In fact the macromolecular chain extends in the direction of carbon-carbon double bond. The methyl group, CH3 and hydrogen being on the similar side shall tend to interfere with each other and therefore the chain shall bend towards opposite side. Thus the rubber like material or elastometer is formed of several chains of molecules which are curled as illustrated in Figure (a), any application of force shall cause these bent or curved molecules to straight configuration as in Figure (b), therefore elongation shall result. Releasing the force shall again allow the chains to bend therefore cause the rubber to regain its original length. The procedure of vulcanisation, mentioned above, creates cross links that do not allow the snarls to straighten up and therefore provide strength. Cross-linking is illustrated in Figure (c).

a) Unstretched (b) Stretched (c) Cross-linking