Engineering Plastics

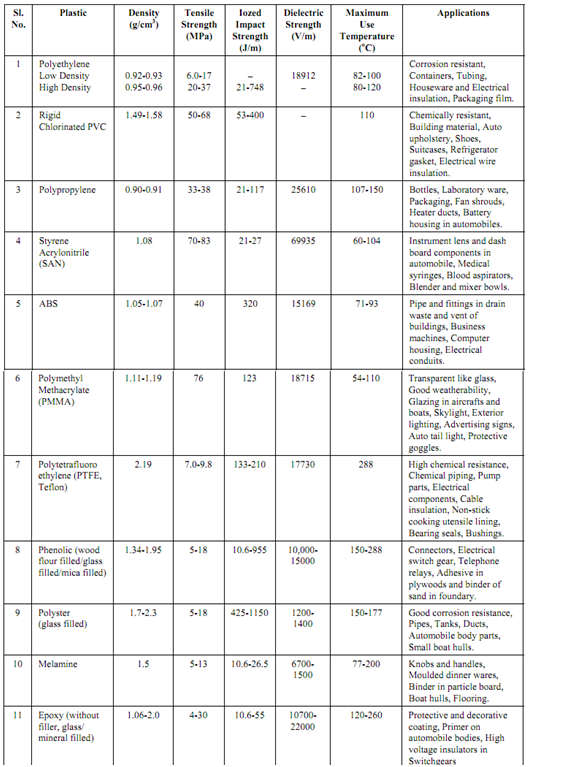

By this time it has become apparent that the plastics are utilized as engineering materials for machine parts, bodies & casting and for structure mainly due to low density although their strength is much less than that of metal. In the field of electrical engineering the plastics are utilized because of their outstanding insulating properties, normally measured in terms of dielectric strength in V/m. Their low melting point is a disadvantage and in several applications the maximum use temperature is also a yardstick. The impact strength of plastics is another significant characteristic and in applications where vibration is likely to take place plastics of low impact strength is not preferred. The ability of plastics to be built in thin foamed structure, walled bags, in different colours and to be recycled (thermoplastics) is added advantages. Their non-degradability has undoubtedly, given increase to problems of ultimate disposal and applications where they might be discarded by users in public places is to be discouraged. Table explained a few plastics, their properties and applications.

TABLE

Note : Materials from Sl. No. 1 to 7 are thermoplastics and Sl. No. 8 to 11 are thermosetting plastics. Thermosetting plastics are utilized with filler.