Natural Polymers

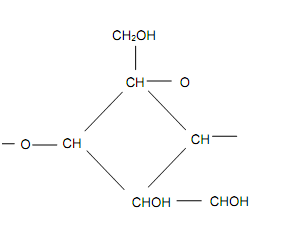

Rubber is one of natural polymer and was explained earlier. Certain trees exude thick liquid which solidified into brittle material called as rosin. Shellac or lac is exudate product of animal life, parasitic insect (coccus lacca) that feeds upon certain trees. This material has very low tensile strength. While dissolved in spirit it might be used for polishing wooden surfaces. Wood is also a naturally occurring polymer whose major constituent is cellulose. The chain molecules of cellulose are highly aligned. This alignment makes wood very directional in mechanical properties. The cellulose molecule is illustrated in Figure.

Figure: Cellulose Monomer of Wood

Wood is a living matter formed of cells which resemble long thin tubes. The walls of these tubes are built with cellulose fibres that are aligned along the axis. A difficult amorphous material called as lignin binds cell walls together, and lignin makes 20 to 35% of wood alongwith 50 to 60% cellulose. Small percentages of gums, resins minerals and carbohydrates are also present in wood. Whereas the density of wood material is constant for all kinds of wood, the presence of voids & cracks of different sizes & numbers cause variation of density from one kind to another. The hygroscopic nature of cell walls causes absorption of water & swelling of wood. These water molecules act very much like plasticiser providing flexibility to wood. Elimination of water makes wood rigid.

Organic acids do not attack wood at room temperature but inorganic acids & alkaline solutions attack wood specifically at higher concentration and temperature. On prolonged heating at 105 to 150oC the organic matter starts to decompose and wood turns black. Wood burns readily giving heat and therefore used as fuel. It might be chemically and mechanically treated to generate wood pulp which is utilized for producing paper.

In spite of the disadvantages of anisotropy and hygroscopicity, wood has been utilized as structural material due to its ready availability, convenient handling and low density. These properties are now better utilized in form of plywood in which odd numbers of 0.5 mm to 1.25 mm thick sheets are joined on surface by phenolic resins along grain directions perpendicular to each other. By compressing wood under high pressure & temperature compressed wood of higher density is generated. This wood is utilized for special purposes. The wood in form of veneers is impregnated with phenolic resin to eliminate water absorption. The thin veneers are bonded together and cured at 150oC to 160oC to generate impreg wood. If this impreg wood is compressed under high pressure and cured at adequately high temperature extremely dense & strong composite laminated wood is produced. It is called as compreg wood. These wood laminates are not only strong and dense but do not absorb water and are not attacked by fungi. They also resist acidic and chemical attack and illustrate dimensional stability.