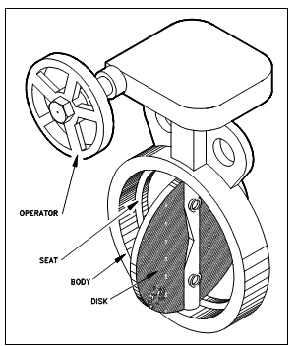

Butterfly Valves:

A butterfly valve, described in below figure, is a rotary motion valve which is used to regulate, stop, and start fluid flow. Butterfly valves are simply and quickly operated since a 90o rotation of the handle moves the disk from a fully closed to fully opened position. Larger butterfly valves are actuated through handwheels linked to the stem by gears that give mechanical benefits at the expense of speed.

Butterfly valves possess several benefits over gate, plug, globe, and ball valves, especially for huge valve applications. Savings in weight, space, and cost are the most obvious benefits. The maintenance costs are commonly low since there are a minimal number of moving elements and there are no pockets to trap fluids.

Figure: Typical Butterfly Valve

These are especially well-suited for the handling of huge flows of liquids or gases at associatively low pressures and for the handling of slurries or liquids along with huge amounts of suspended solids.

Butterfly valves are built on the principle of a pipe damper. A flow control components is a disk of around the similar diameter as the inner diameter of the adjoining pipe that rotates on either a vertical or horizontal axis. While the disk lies parallel to the piping run, a valve is fully opened. While the disk approaches the perpendicular position, a valve is shut.

Middle positions, for throttling reasons, could be secured in place through handle-locking devices.