Tool Length Compensation

So far we did not put much emphasis on the tools used in the program. All the programs were using a single tool, which did not pose a problem. However, when a program uses multiple tools, it is a fact that all the tools are not of identical length. That means the Z coordinate programmed for each of the tool will have to take into account the actual tool height.

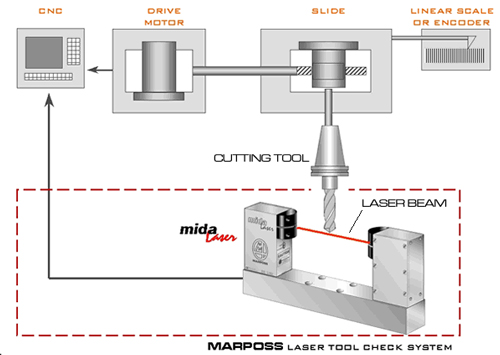

Figure 13 : Tool Length Compensation

All the tools used in NC should be assembled and measured using a tool presetter with their lengths as shown in Figure 13. The NC program will be developed generally using the longest tool, while for the other tools the difference in length as measured from the tool presetter is entered into the control in the form of tool offsets. Generally, the tool offset values are associated with the tool numbers as entered in the program as follows :

---------------------

Ν015 Μ06 Τ01

---------------------

---------------------

Ν065 Μ06 Τ02

---------------------

---------------------

The CNC control automatically compensates for the difference in the length of the tools when that particular tool is brought into operation.