Primary Combustion:

In this pure oxygen reacts along with hydrocarbon fuel gases to generate hydrogen and carbon. Partially combusting the carbon to CO. This occur in the core of the flame known as innercone.

Secondary Combustion:

In this carbon monoxide is oxidised by oxygen from the air neighbouring the flame, and the hydrogen is burned to form water vapour. This procedure takes place in the outer portion of the flame.

Flame temperature differ according to the type of oxygen and fuel to fuel ratio. Velocity of flame travel through adjacent unburned gas is called as flame propagation rate. It effect the size and temperature of the primary flame. this also influences the maximum velocity at which gases might be made to flow from the torch tip without causing a flame standoff or backfire. In case of flame standoff combustion occur some distance from the torch tip instead of right at the tip whereas in case of backfire there is recession of flame into the torch tip.

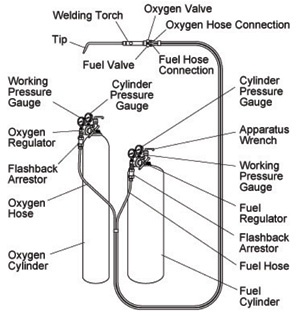

The oxyfuel procedure requires cylinder of oxygen and fuel gas (Figure 8). Each cylinder is fixed along a regulator and two pressure gauges (one for the pressure in cylinder and the other one for the pressure of gas being fed to the torch).

Figure: Oxyfuel Welding - Schematic Diagram of the Process;

Natural gas/methane, butane, propane or hydrogen might be used with oxygen but oxy acetylene welding (OAW) in which acetylene is utilized with oxygen is most broadly used welding method because of its high flame temperature. The oxyacetylene flame might also be utilized for all types of brazing processes. Oxyacetylene flame might be carbursing (excess acetylene with oxygen) that is blue with a red and orange end, an oxidising frame (excess of oxygen) resultant in short hoisy, hissing inner cone. Oxidising flame tends to burn the metal being welded. However the neutral flame (perfect mixture of oxygen & acetylene) which has a quiet, blue white inner cone is best suitable for most welding procedure.