Vickers Hardness

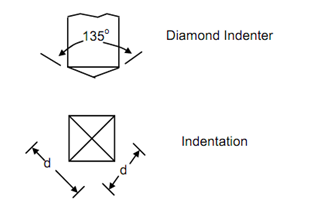

Basically Vickers hardness is same as Brinell hardness in that an indentation is made under a load P and the Vickers hardness number is defined as the ratio of load P to the surface area of the indentation. The difference between two test methods lies in use of indenter. The Vickers indenter is a diamond pyramid with square base and included angle between opposite faces as 136o. The impression of this indenter has square boundary with depression inside. The lengths of two diagonals are measured under microscope and average is used to calculate the surface area of indentation.

Thus, Vickers hardness number,

VHN =( 2 P sin (θ / 2)) / d 2+1.854 P/ d 2 --------- (20)

here, P is the indenting load in kgf. d is the average of two diagonal and θ is the angle between opposite faces of diamond come which is 136o.

Figure : Diamond Indenter and its Square Indentation in Vickers Hardness Test

The impression of the diamond cone is square under any load, hence the impressions are geometrically similar irrespective of load. This provides a great convenience of a continuous scale from very soft material to very hard material without changing the load or indenter. Generally for a given load hardness from 5 to 1500 VHN can be measured with Vickers indenter, and it makes VHN independent of load except at very high loads. However, loads between 1 kgf to 120 kgf are commonly used for VHN measurement for very soft to very hard metals. For the reason of independence of VHN of load, this method has widely been accepted as a research tool.

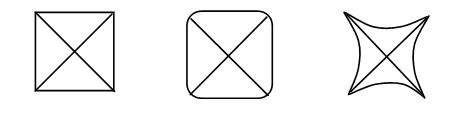

However, Vickers hardness measurement cannot be made on poorly finished surfaces and an element of personal error is introduced because of accurate measurement of the diagonal of indentation. In addition, the “anomalies of ridging” in case of cold worked metals and of “sinking in” in case of annealed metals are also observed in Vicker’s impression as in case of Brinell indentation. The barrel shape of indentation causes an apparent increase in hardness due to “ridging”. Pin-cushin shape of indentation causes an apparent decrease in VHN due to sinking in as shown in Figure 33 along with perfect Vickers indentation.

Figure : (a) Perfect Indentation of a Diamond Pyramid; (b) Barrrel Shaped Impression due to Ridging; and (c) Pin Cushion Shaped Impression due to Sinking In