Development of computer controlled HPLC systems:

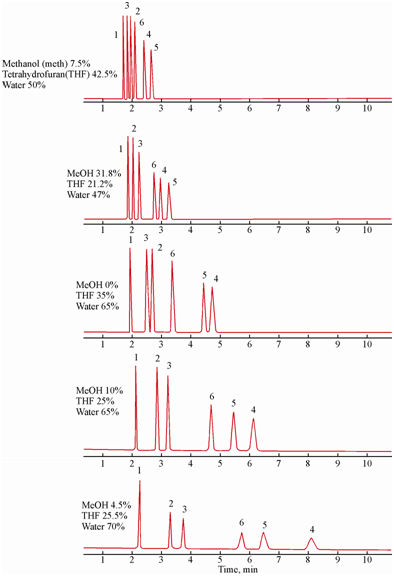

The development of computer controlled HPLC systems has enabled systematic automatic optimization techniques based on statistical experimental design and mathematical resolution function. First of all column (stationary phase) and detector are carefully chosen followed by the mobile phase composition and other parameters such as flow rate, temperature etc. Though this can be done manually but computer controlled optimization has several advantages. Sometimes gradient elution is used as a preliminary step for unknown samples so as to indicate mobile phase composition conditions. A typical example of parathion of a six component mixture using five different proportions of methanol, tetrahydrofuran (THF) and water is illustrated in Figure. It is observed that as the water content is increased and the composition of methanol and tetrahydrofuran is adjusted, six peaks corresponding to benzyl alcohol, phenol, 3-phenylpropanol, 2, 4-dimethylphenol, benzene and diethyl o-phthalate are better resolved.

Figure: Illustration of optimization of HPLC separation conditions using five ternary phases. Peaks; 1. Benzyl alcohol, 2. Phenol, 3. 3-Phenylpropanol, 4. 2,4-dimethylphenol, 5. Benzene, 6. Diethyl o-phthalate

If complete separation is required in minimum possible time then first chromatogram is the method of choice. If internal standard is to be added within a space of chromatogram then either of next two chromatograms may be used. However, if reaction products need to be separated or impurities are expected then any one of the last two methods best meets the requirement.