Milling Operation

The elimination of metal by advancing a workpiece against a rotating multiple point tools is termed as Milling. Generally, milling operation is divided into 2 types:

1. Slab Milling

2. Face Milling

Slab Milling

Generating the slot on the surface of workpiece is called slab milling operation. The geometry of the chip produced by slab milling based upon the path followed by the cutting edge. The milling cutter rotates at uniform velocity and the workpiece feed linearly under the cutting edge. Consequently the tip of the cutting tool traces a trochoid.

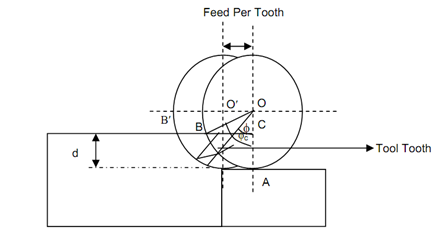

Figure: Slab Milling

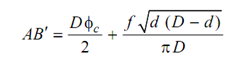

In the up milling operation the chip begin with zero thickness at A and reaches the maximum thickness at B′. The length of the chip AB′ in case of up milling is given by

Equation 1

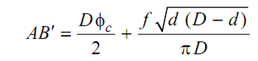

In case of down milling, the chip length is given by

Equation 2

The difference in the chip length is comparatively small and depends upon the increase in feed rate.