Column Operation:

Column operation can be visualized as a large number of batch operations in series. The extent to which the exchange takes place in each one of these small batch operations is limited by the appropriate selectivity coefficient, the overall effect may be much more favourable. A successive batch operation within a simulated column may be considered to plates in a distillation column. In a majority of units, ion exchange containers are used and they are taken as vertical columns filled with ion exchanger. The resin is supported on a bed of graded gravel or some other filter base and the feed and regenerant solution passed through the column (down-flow operation) or up through the resin (up-flow operation).

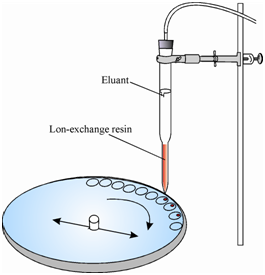

Figure: Ion exchange column with fraction collector

Generally, fixed bed units are used with down flow operation. It gives a maximum of resin solution contact and a minimum of mechanical problems. A fixed bed ion exchange column may be operated with counter-current flows. In such a system, the feed is put through the column down flow and the regenerant is put through up-flow and vice-versa. A Huge number of column arrangements have been designed in which multiple column are piped together to give semi-continuous operations, maximum resin utilization, regenerant recovery or some other improvements.