Operations of a Numerical Control Machines

Numerical control (NC) of machine tools might be defined as a method of automation incorporated into the machine tools that may be carried out through numbers, letters and symbols. It helps that a NC machine tool runs on a part program fed to it. The part program has precise instructions regarding the way the part is to be manufactured in terms of the table movements. Some typical instance could be what tool to be utilized, at what speed, at what feed and to move from which point to which point in what path.

Since the program is the controlling point for product manufacture, the machine tool becomes flexible and can be used for any part that falls in its part spectrum. All of the functions of a NC machine tool are therefore controlled through an external power source, which might be hydraulic, electronic and/or pneumatic.

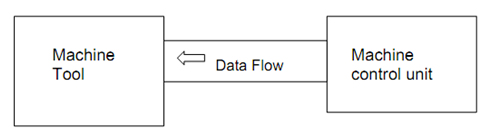

The principle of operation of a NC machine tool is shown in Figure 2.

Figure 2 : Principle of Operation of a NC Machine Tool

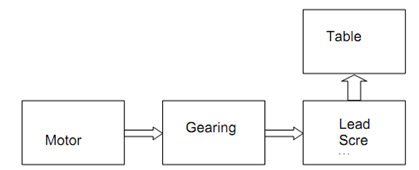

The part geometry, cutting process parameters and the cutting tools used will be input into the system. This part program is then entered into the controller of the machine that in turn runs the machine tool to make the part as shown in Figure 3.

Figure 3: Typical Operation of the Controlled Axis in a NC Machine Tool