Grouping Related Surfaces or Areas

When several areas or surfaces are related in such a way that they can be accomplished in one setting of the workpiece, considerable savings can usually be attained. For this reason, when the process engineer attempts to establish the relationship between surfaces, he should also be concerned with grouping them for economy.

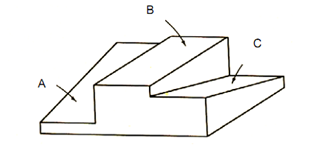

Some surfaces, though closely related dimensionally, cannot be combined readily for machining because of differences in surface position. Two surfaces bearing an angular relationship to each other may be difficult to combine because they cannot be matched with the geometry the machine was built to produce. For example, in Figure each of the three surfaces bear a specific relationship to the base of the object. Surface B is parallel to the base of the object, but surfaces A and C are at angles to the base and at opposite angles to each other. It is obvious that all three surfaces could not be gang milled at one pass. The object in Figure would not present such a problem, for all surfaces were parallel.

Figure 5: Sketch Showing Surfaces, which are not Related to can be Conveniently Combined the Degree, Those Operations on Them