Magnetic Controller:

A large % of controller applications needs in which the controller be operated from a remote location or operate automatically in response to control signals. As elaborates, manual controllers cannot give this type of control; thus, magnetic controllers are necessary.

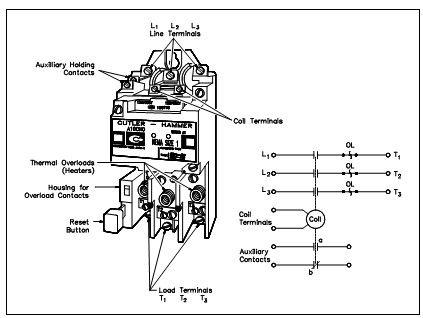

Basic operations by using a magnetic controller, like as the closing of switches or contacts, are performed through magnetic contactors. A magnetic controller is one which will automatically perform all operations in the proper sequence after the closure of a master switch. A master switch (for instance, float switch, pressure switch, or thermostat) is often operated automatically. But in a few cases, like as drum switches, pushbuttons, or knife switches, a master switch is manually operated. Above Figure display a typical magnetic controller and its component elements.

Figure: Typical Three-Phase Magnetic Controller

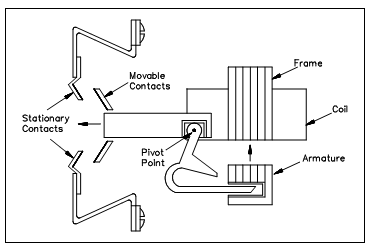

A magnetic contactor that was display in above figure is a device operated through an electromagnet.

The magnetic contactor consists of an electromagnet and a movable iron armature on that movable and stationary contacts are mounted. While there is no current flow by the electromagnetic coil, an armature is held away by a spring. When the coil is energized and the electromagnet attracts the armature and closes the electrical contacts.

Overload devices are incorporated into magnetic controllers. Those overload devices are protect the motor from overcurrent conditions which would be extremely harmful. There are various categories and forms of overload devices. The subsequent categories of overload devices are generally used in motor-control equipment.

1. Fuses

2. Thermal overloads

3. Magnetic overloads

The thermal overload device is display in above Figure.

Figure: Magnetic Contactor Assembly