Face Milling

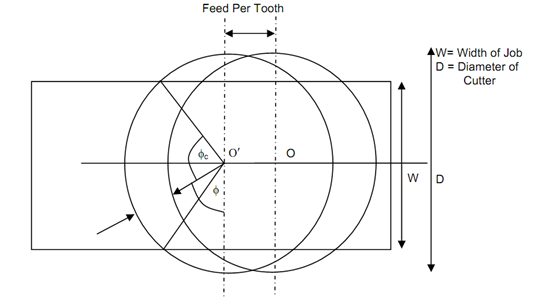

Elimination of thin layer of material from flat workpiece is called face milling operation. To arrive at chip thickness, we have considered Figure where the top view of face milling is illustrated. It is again supposed here that the face mill is symmetrically located above the workpiece to simplify the analysis.

Figure: Cross-section for the Chip Produced by Milling using a Face Milling Cutter with Symmetrical Cut

The tooth angle, φc, in case of face milling is given by

sin φc = (W /2 ) /(D/2) = W/D eq.(1)

The chip thickness at any section is specified by

tx = ft Sin Φ eq.(2)

where, ft = feed per tooth.

The smallest chip thickness is at the edge of the workpiece while the maximum is at the centre of the workpiece. The angle at the minimum chip thickness is

Φ =( π/2 ) - ( Φ c /2) eq.(3)

Hence, tmin = ft cos Φc

Similarly, tmax = ft