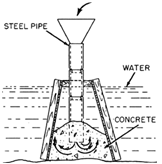

Tremie Method:

It is a watertight pipe having a funnel shaped hoper at its upper end and loose plug at the bottom or discharge end. That is diameter about 250 mm. To dewater the tremie and control the distribution of concrete the valve at the discharge end is used. The tremie is built up in 1 to 3.5 m sections. It is supported into a working platform above water level. The water and air must be excluded from the tremie by keeping the pipe full of concrete all the time during concrete. The capacity of the hopper should be at least equal to that of tremie pipe. A plug formed of paper is first inserted into the top of the pipe in charging the tremie. As the hopper is filled, the pressure of fresh concrete forces the plug down the pipe, and the water in the tremie is displaced by concrete. To concreting the tremie pipe is lowered into position and the discharge end is kept as deeply submerged beneath the surface of freshly placed concrete as the head of concrete in tremie permits. The pipe is raised slightly as concreting proceeds and the concrete flows outward. Care should be taken to maintain continuity of concreting without breaking the seal provided by the concrete cover over the discharge end. The tremie should never be moved laterally through freshly placed concrete. The tremie should be lifted vertically above the surface of concrete and shifted to its new position. When large quantities of concrete are to be placed continuously, place the concrete simultaneously and uniformly through a battery of tremies, rather than shift a single tremie from point to point. The segregation and non-uniform stiffening can be minimized by maintaining the surface of concrete in the forms as level as possible and by providing a continuous and rapid flow of concrete. The spacing of tremies recommended between 3.5 m and 5 m and that the end tremies should be about 2.5 m to the formwork.

Figure: Typical Arrangement for a Tremie Pipe