Roll Over Machine

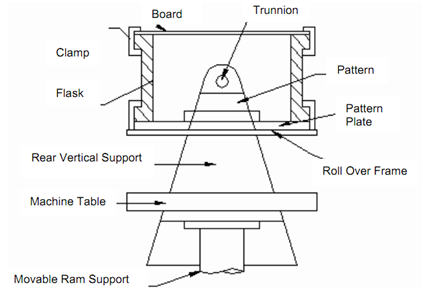

Roll over Machine contains a rigid frame carrying two vertical supports on its either sides involving the bearing supports of trunnions. The roll over frame of the machine is mounted on the trunnions. The pattern plate is situated on roll over frame of the machine. The pattern is mounted on the pattern plate. The standard of working of a roll over machine is displayed in below diagram.

Figure: Working Principle of Roll over Machine

The roll over frame is clamped in a position along with the pattern facing upward for completing the mold. The flask is located over the pattern plate and is clamped. Sand is filled in it and is rammed through hand. The excess sand is removed and molding board is positioned over the flask and clamped. After that roll over frame is unclamped and rolled over through 1800 to suspend the flask below the frame. The pattern is then lifted up to push in opposition to the suspending flask. The flask is unclamped from the pattern plate to rest over the platen that is brought down when leaving the pattern attached to the plate. The frame is once again rolled over to original position in order to ram another flask. Appropriate mechanisms are included to allow rolling over and platen motion.