Tension Test

A tension test is a destructive test in the sense that the specimen is ultimately broken or fractured into pieces. For performing a tension test one needs a machine capable of applying load to cause fracture. The testing machine shall have suitable devices or holders to hold the specimen so that a perfectly axial load is applied on the test piece. The machine has to have device to measure the load at any instant & facility for measurement of elongation of the test piece.

The test piece or specimen of the material is usually a straight piece, uniform in the cross-section over the test length and frequently with enlarged ends which may be held in the machine holders. Machines, however, may hold specimen without specially made or enlarged ends. Two fine marks are frequently made near the ends of uniform test section of the specimen and distance between the two points is termed "gauge length". The gauge length of any specimen bears a constant standardised ratio to the cross-sectional dimension for reasons that will be discussed later.

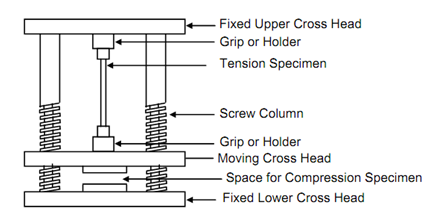

Figure: The Schematic Diagram of a Test Machine

The specimen is placed in the machine between the holders and any measuring device to record alter in length is fitted onto the specimen between the gauge points. If such a device, often known as "extensometer" is not fitted, the machine itself might record the displacement among its cross-heads on which the specimen is held.

Once the machine is started it starts to apply a slowly increasing load upon the specimen. At present intervals the reading of load & elongation of specimen are recorded. Enhance in extension may be observed from the specimen and as the extension begins to enhance can be observed from the specimen and as the extension begins to rise at a faster rate (it can be judged from experience) the extensometers if associated to specimen might be removed. With further enhance in the load the extension increases at enhanced rate and record of extension may be obtained from displacement among the cross-heads. At some level the load becomes stationary & the specimen either fails or begins to decrease in cross-section rapidly. The latter phenomenon is known as necking & is followed by reduction in load accompanied by further extension until the specimen fractures into two pieces.