Compression of Brittle Materials

For most brittle materials the elastic properties like elastic limit, modulus of resilience, yield strength and modulus of elasticity are same in tension and compression. The ultimate compressive strength of most brittle materials is different than the ultimate tensile strength. For example, in concrete, the ultimate compressive strength is about ten times its ultimate tensile strength.

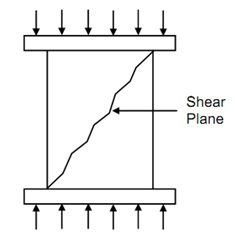

The compression test specimen fractures because of shearing along a plane inclined to the axis. The orientation of the plane of shear is affected by the presence of normal compressive stresses and the final fracture does not often occur along plane of maximum shearing stress which is inclined at an angle of 45o with the axis. The orientation of plane of shear varies between 35o and 45o with the axis.

Figure: A Brittle Material Specimen under Compression

Even in brittle materials some lateral bulging will tend to occur. This lateral deformation is greatly restricted at flat specimen ends due to friction between the platens and the specimen ends. This friction reduces for longer specimen. If the compression specimen is too long, it may have a tendency to buckle. To minimise the influences of friction and buckling the length to diameter ratio of compression specimen has to be chosen very carefully. For determination of compression strength this ratio is between two and three.

However, for determination of elastic properties the ratio of length to diameter may be chosen between eight and ten. If value of this ratio is less than 1.5 the fracture plane might intersect the end which is undesirable.It may be noted that the brittle material in which the atomic bonds are not re-established will ultimately fracture due to slip which may occur along one or several planes. The later failure is fragmentation. While the cracks, pores and holes play very important role in reducing tensile strength the same do not become active under compressive stress.

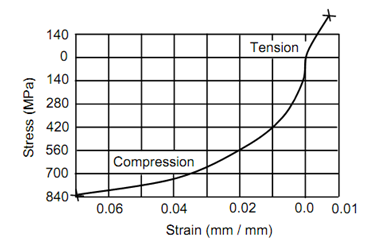

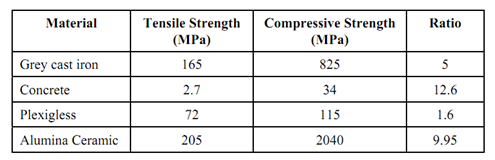

They rather close and net compressive strength is higher than tensile strength particularly in case of brittle materials. Figure 18 shows this fact for cast iron, and Table describes the same for several materials.

Figure: Stress-Strain Diagram for Cast Iron in Tension and Compression

Table 2 : Tensile and Compressive Strength of Brittle Materials

[Note : Concrete 1.3 mix by volume, water cement ratio 0.64 (by volume) cured for 28 days.]

Compression test is terminated if excessive deformation occurs and specimen does not fracture.

The hydrostatic compression is the loading in which every element is subjected to equal compression stresses in all three directions. This state of stress which is obtainable when a body is submerged in water does not cause any distortion but produces only volume reduction. In such a test the specimen my not fail at all because at atomic level such state of stress will tend to push atoms into each other and no slip would occur, hence no plastic deformation.