Two-Phase Fluid Flow

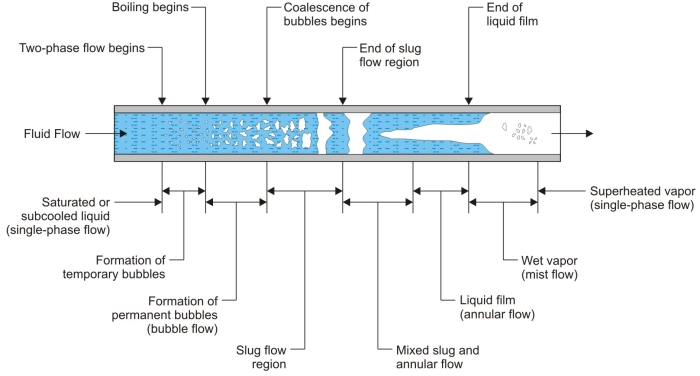

All of the fluid flow associations are for the flow of a single phase of fluid whether it is liquid or vapor. At certain significant positions in fluid flow systems the concurrent flow of liquid water and steam takes place, termed as two-phase flow. These easy associations used for examining single-phase flow are inadequate for examining two-phase flow.

There are numerous methods employed to predict the head loss due to fluid friction for two-phase flow. The two-phase flow friction is greater than the single-phase friction for similar conduit dimensions and mass flow rate. The difference emerges to be a function of the kind of flow and outcomes from raised flow speeds. The two-phase friction losses are experimentally established by measuring pressure drops across various piping elements. The two-phase losses are commonly associated to single-phase losses via the similar elements.

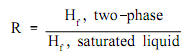

One accepted methods for determining the two-phase friction loss depend on the single-phase loss includes the two-phase friction multiplier (R) that is defined as the ratio of the two-phase head loss divided by the head loss computed by using saturated liquid properties.

Here:

R = two-phase friction multiplier

Hf, two-phase = two-phase head loss due to friction (ft)

Hf, saturated liquid = single-phase head loss due to friction (ft)

The friction multiplier (R) has been found to be much higher at lower pressures than at high pressures. The two-phase head loss can be a lot of times greater than the single-phase head loss.

However a broad range of names has been employed for two-phase flow patterns, we shall define only three kinds of flow. The flow patterns to be employed are stated as follows:

1. Bubbly flow: there is dispersal of vapor bubbles in a continuum of liquid.

2. Slug flow: in bubbly flow, the bubbles rise by coalescence and eventually become of the similar order of diameter as the tube. This produces the usual bullet-shaped bubbles which are characteristic of the slug-flow regime.

3. Annular flow: the liquid is now distributed among a liquid film flowing up the wall and a dispersal of droplets flowing in the vapor core of the flow.