Heat Exchangers

The transfer of thermal energy among fluids is one of the most significant and often used procedures in engineering. The transfer of heat is generally achieved by means of a device termed as a heat exchanger. The general applications of heat exchangers in the nuclear field involve fan coolers, boilers, cooling water heat exchangers, & condensers.

The fundamental design of a heat exchanger generally has two fluids of various temperatures divided by some conducting medium. The most general design has one fluid flowing via metal tubes and the other fluid flowing about the tubes. On either side of the tube, the heat is transferred by convection. The heat is transferred via the tube wall by conduction.

The heat exchangers might be separated into numerous groupings or classifications. In the most generally employed kind of heat exchanger, the two fluids of various temperature flow in spaces divided by a tube wall. They shift heat by convection and by conduction via the wall. This kind is termed to as an "ordinary heat exchanger," as compare to t other two kinds classify as "regenerators" and "cooling towers."

The ordinary heat exchanger is single-phase or two-phase. In a single-phase heat exchanger, both the fluids (cooled & heated) stay in their initial gaseous or liquid states. In 2-phase exchangers, either of the fluids might change its phase throughout the heat exchange procedure. The steam generator and chief condenser of nuclear facilities are of the 2-phase, ordinary heat exchanger categorization.

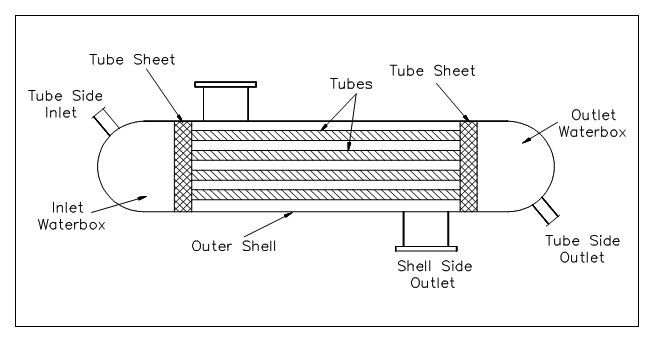

The Single-phase heat exchangers are generally of the tube-and-shell kind; that is, the exchanger contains set of tubes in a container termed as a shell (the figure is shown below). At the ends of the heat exchanger, the tube-side fluid is divided from the shell-side fluid through a tube sheet. The design of two-phase exchangers is necessarily the similar as that of single-phase exchangers.

Figure: Typical Tube and Shell Heat Exchanger