Boiling Heat Transfer

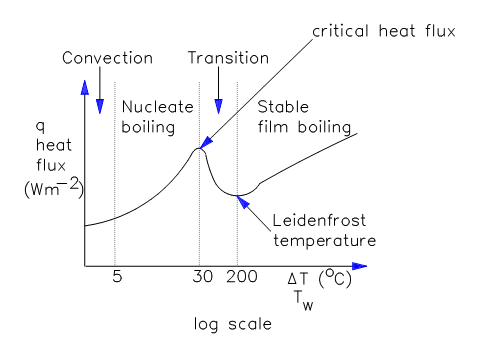

The Boiling is related with transformation of liquid to vapor by heating. The creation of bubbles stirs the fluid and breaks the boundary layers therefore raising the heat transfer coefficient. It vary from vaporization in the logic that it is related with the formation of bubbles. The bubbles are generally formed on the surface scratches. The bubbles do not emerge till the wall is heated in surplus of the saturation temperature, termed as the wall superheat.

Boiling is the most efficient heat transfer technique since of its high performance due to latent heat transport, therefore permitting to decrease weight, size, and volume of heat exchange devices and enhance the thermal performance of components for the process industry and power plants. Hence, boiling heat transfer plays a very significant role for a large number of applications in many technological and industrial regions, involving energy production. As an illustration, sub-cooled boiling heat transfer can accommodate very high heat fluxes, and this can be duly used in the cooling of some components for fusion reactors, where it is needed to eliminate up to 10-15 MW/m2. Moreover, very compact heat exchangers can be manufactured, gratitude to the high heat transfer rate acquired with boiling heat transfer. The steam generators can be better designed when the boiling process is well-known in detail, therefore improving the thermal cycle and the plant effectiveness.