Rotary Compressors:

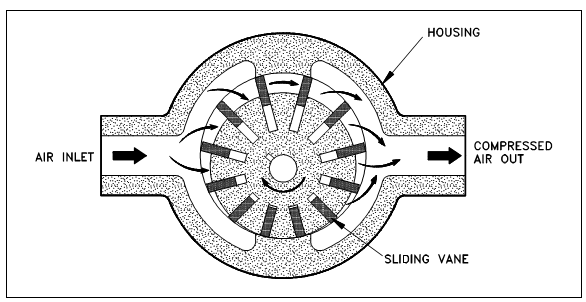

The rotary compressor is adaptable to direct drive through induction motors or multicylinder diesel or gasoline engines. The units are compact, associatively inexpensive, and needs a minimum of operating attention and manage. That occupies a fraction of the space and weight of a reciprocating machine of equal capacity. Rotary compressor units are categorized within three common groups, lobe-type, slide vane-type, and liquid seal ring-type. A rotary slide vane-type, as described in Figure, has longitudinal vanes, sliding radially within a slotted rotor mounted eccentrically inside a cylinder. The centrifugal force carries the sliding vanes against the cylindrical case along with the vanes by forming a number of individual longitudinal cells inside the eccentric annulus among the case and rotor. A suction port is situated whereas the longitudinal cells are largest. A size of every cell is decreased through the eccentricity of the rotor as the vanes approach the discharge port, therefore compressing the air.

Figure: Rotary Slide Vane Air Compressor

The rotary lobe-type, described in Figure, characteristics two mating lobe-type rotors mounted in a case. A lobe is gear driven at close clearance, other than without metal-to-metal contact. Suction to the unit is situated whereas the cavity made through the lobes is largest. Since, the lobes rotate then the cavity size is decreased, causing compression of the vapor within. A compression continues until the discharge port is reached, at that point the vapor exits the compressor at a higher pressure.