Compressor Coolers:

The amount of moisture in which air could carry is inversely proportional to the pressure of the air. Since the pressure of the air increases then the amount of moisture that air can hold decreases. The amount of moisture that air could hold is also proportional to the temperature of the air. While the temperature of the air increases then the amount of moisture it could hold increases. Therefore, the pressure modifies of compressed air is larger than the temperature change of the compressed air.

This causes the moisture within the air to condense. Moisture in compressed air systems could cause serious damage. Condensed moisture could cause corrosion, water hammers and freeze damage; therefore, it is important to prevent moisture within compressed air systems. The Coolers are used to minimize the problems caused through heat and moisture within compressed air systems.

Coolers used on the discharge of a compressor are known as aftercoolers. Their reason is to erase the heat produced during the compression of the air. The decrease within temperature promotes the condensing of any moisture present inside the compressed air. That moisture is collected within condensate traps which are either automatically or manually drained.

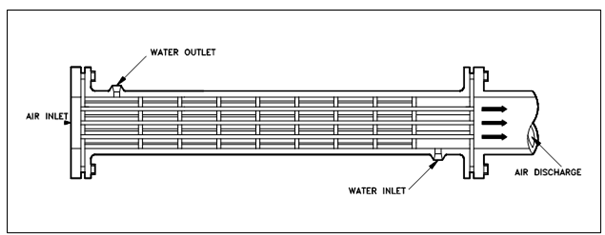

There might be an intercooler if the compressor is multi-staged, that is commonly situated after the first stage discharge and before the second stage suction. A principle of the intercooler is the similar as in which of the aftercoolers. The output is cooler, drier, compressed air. A structure of a particular cooler depends on the pressure and volume of the air it cools. Figure described a classical compressor air cooler. Air coolers are used since drier compressed air helps avoids corrosion and cooler compressed air permits more air to be compressed for a set volume.

Figure: Compressor Air Cooler